The best slitting technology for dry or squeezed wet fabrics!

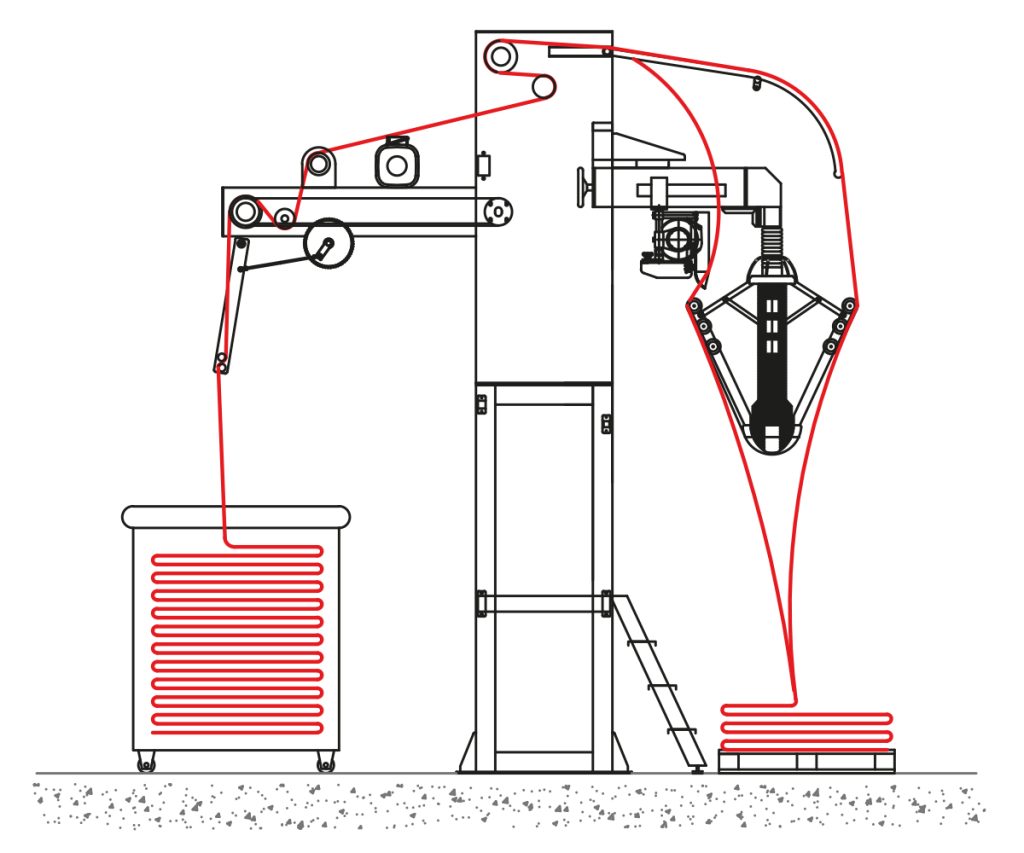

ST-SLIT designed for slitting the tubular form wet or dry squeezed fabrics in order to marking open width form by means of the tube slitting equipment.

▪ Drop stitch matrix sensor detects the drop stitch using the transmitted light principle.

▪ Rapid positioning of the drop stitch at the beginning of production through LED basket inner lighting.

▪ Stable closed loop with position, speed and current controller.

▪ The roller basket guarantees the minimum longitudinal tension for dry and wet fabrics.

A tube in the form of raw, dyed, and damp fabrics with photocell-controlled automatic vertical and manual cutting with a knife along the line may, the opening of the fabric engaging rollers so it provides easily

placed in carrier.

| WORKING WIDTH | 2400 mm. |

| WORKING SPEED | 90 m/min |

| ELECTRICITY CONSUMPTION | 4 kW +/-5% |

| CUTTING DEVICE SPEED | 1800 m/min |

| VOLTAGE | 380-440V, 50-60 Hz |