Squeeze padder is a great interest due to the ease of operation. It provides a lot of comfort areas. The power of the tightening effect is comparable to the size of human power. This also ensures that many transactions are made in a short time. This is the rollers. These are called padder and make all the jobs largely. Engines work with the help of rotary tables. The direction of rotation can be changed according to the need. This depends on what direction of the clamping process to be done in the direction. Clockwise or in the opposite direction.

Fabrics are undergoing a process called impregnation primarily before adding a chemical substance or only to remove the water inside. A process similar to the baking is applied to here. With the evaporation method, the amount of water in the fabric is reduced. Then the squeeze padder process is passed through the rolls.

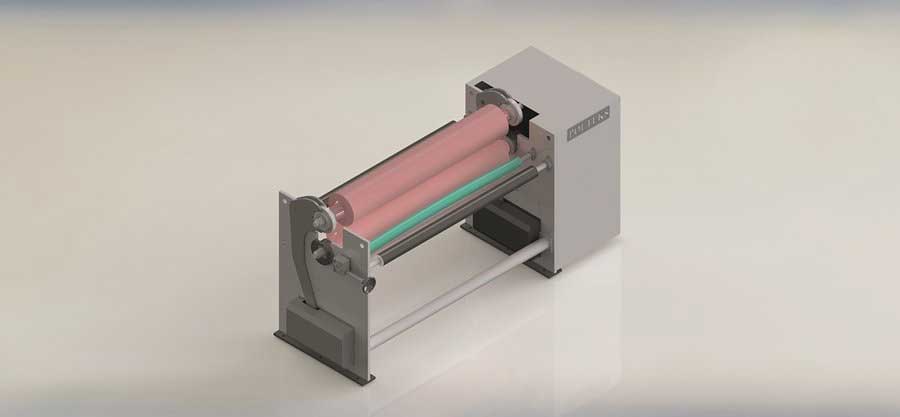

Padder

A padder is a machine used in textile processing, in particular. Finishing describes the treatment of fabrics and textiles to enrich them with a specific feature. Prior to the treatment the liquor is added to the pattern the textile will be soaked with the liquid in general and emulsion. Two counter-rotating rollers hold this liquid once the fabric is thread between the rollers from the top.

It will be saturated evenly with the liquor a predefined pressure is applied to the rollers and squeezes the fabric to the desired level of moisture this is also referred to as liquor pick up. After the squeezing process the fabric is generally dried on at enter. Padder works with a variety of machines. Nowadays it is not only used for drying. It is also used for painting, polishing and squeezing. It does many things that are desired using very little energy.