Efficient production standards with ACT AUTO…

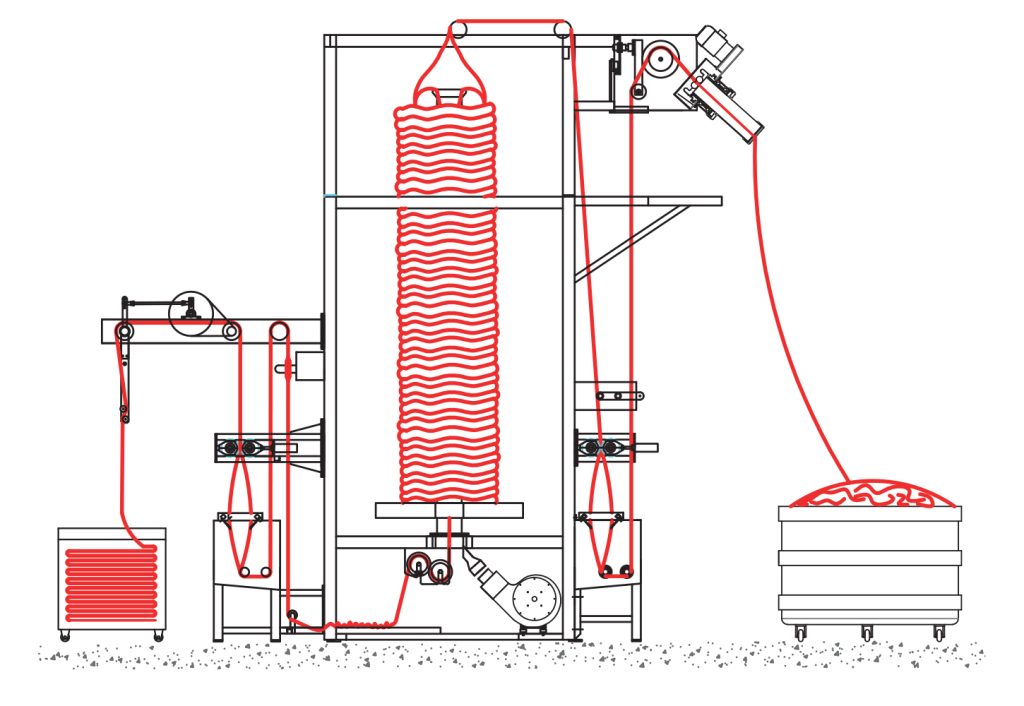

It is designed for Reversing of tubular form wet fabrics and removal of enzymatic waste from the internal and surface of fabrics

HOW IT WORKS

▪ Wet fabric pass trough the Reversing pipe.

▪ Fabric accumulated on to the carrier lift.

▪ Reversed fabric pass trough the washing bath.

▪ Will be plaited with the help of plaiting unit.

▪ DE-Twister used to remove any tension from the rope. It ensures optimum untwisting without elongation.

▪ 1st squeezing unit consist from water spraying system with the squeezer cylinder.

▪ Hydraulic system elevator with airflow will accumulated wet fabric in best shape.

▪ 2nd squeezing unit consist from water spraying system with the squeezer cylinder.

▪ Polyamide ring group on inlet and exit of the machine for detecting the width of fabric.

▪ Enyzme washing & Turning Filter Unit enzyme dust on the fabric are cleaned. It will separate and recycle the water from enzymatic waste with antipilling Turning filter unit.

| WORKING WIDTH | 1200 mm. |

| MACHINE SPEED | 80 m/min |

| ELECTRICITY CONSUMPTION | 6 kW +/-5% |

| VOLTAGE | 380-440V, 50-60 Hz |

| AIR PRESSURE | 6 bar |

| WATER CONSUMPTION | 0.5 m³/h |