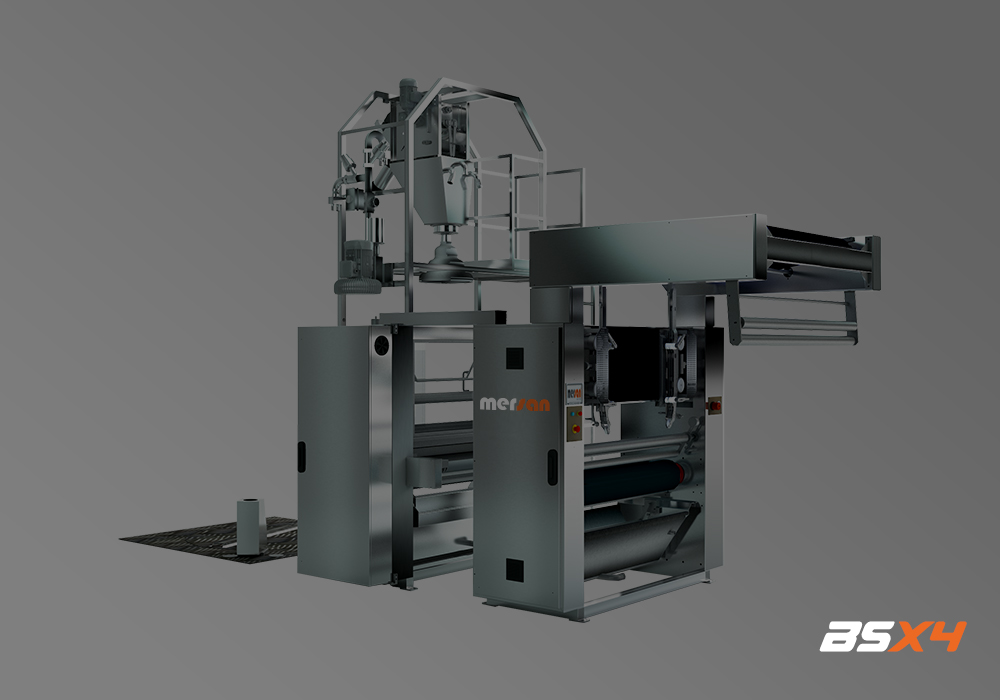

High production speed and high productivity with Mersan BS X4!

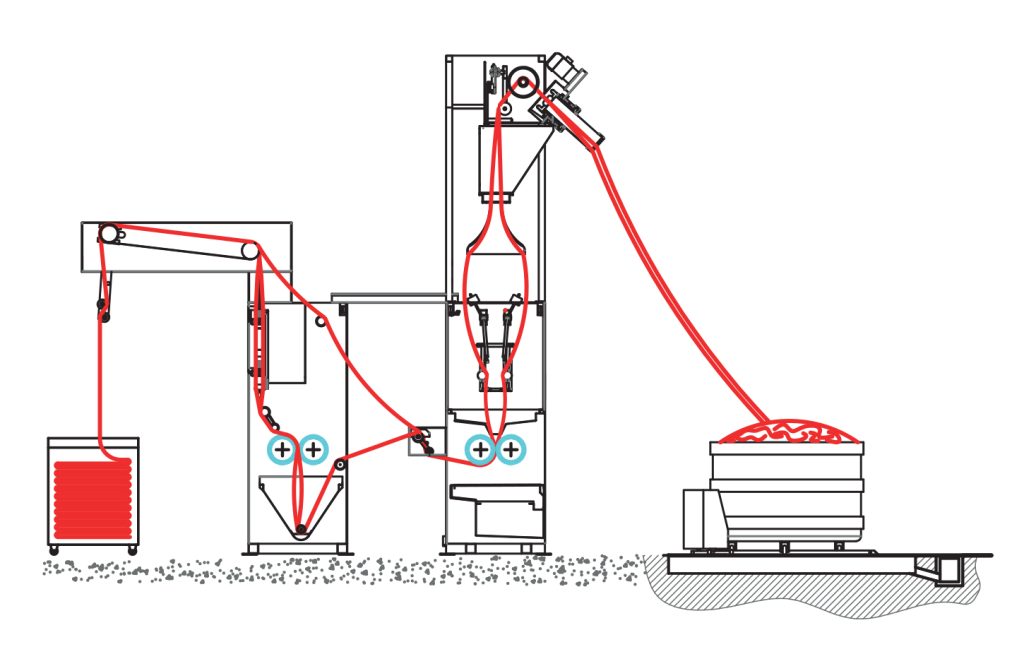

After the dyeing process the wet knitted fabric need to be open from the rope form and achieve the lower residual moisture by the squeezing.

Turn Table the fabric trolley rotation will makes the

untwisting of the fabric easier by operating in synchrony with the DE- Twister. The structure is completely in stainless steel and designed for processing even heavy

▪ DE-Twister used to remove any tension from the rope. It ensures optimum untwisting without elongation.

▪ Blower with Pump for create the fabric balloon under the DE-Twister immediately.

1st Foulard consist of two rubber rollers for squeezing the fabrics.

▪ 2nd Foulard for the used to impregnate fabrics with

chemical. Fabric silicone-finishing chemicals 10-20% upon receiving on balloon squeezing process.

▪ Magnetic Stretcher for obtain the best desired width for the fabric.

▪ Mixer Tank designed for the preparation of chemical products to be applied to fabric.

| HEATED DRUMS WIDTH | 1600 mm. |

| WORKING WIDTH | 250-1200 mm. / At stretcher 1300 mm. |

| MAGNETIC STRETCHER & FEEDING | Magnet system / %20 Fabric feeding |

| WORKING SPEED (Max.) | 80 m/min |

| VOLTAGE | 380-440V, 50-60 Hz |

| ELECTRICITY CONSUMPTION | 19 kW +/-5% |

| WATER CONSUMPTION | 0.5 m³/h |

| AIR PRESSURE | 0-6 bar |

| SQUEEZING FOULARD CYLINDERS | Ø 250 mm rubber / 90-95 Shore A |

| IMPREGNATION FOULARD CYLINDERS | Ø 250 mm rubber / 80-85 Shore A |