High processing quality with exceptional shrinking results!

Achieve minimum residual shrinkage values with optimum fabric hand and reliable reproducibility for knitted fabrics.

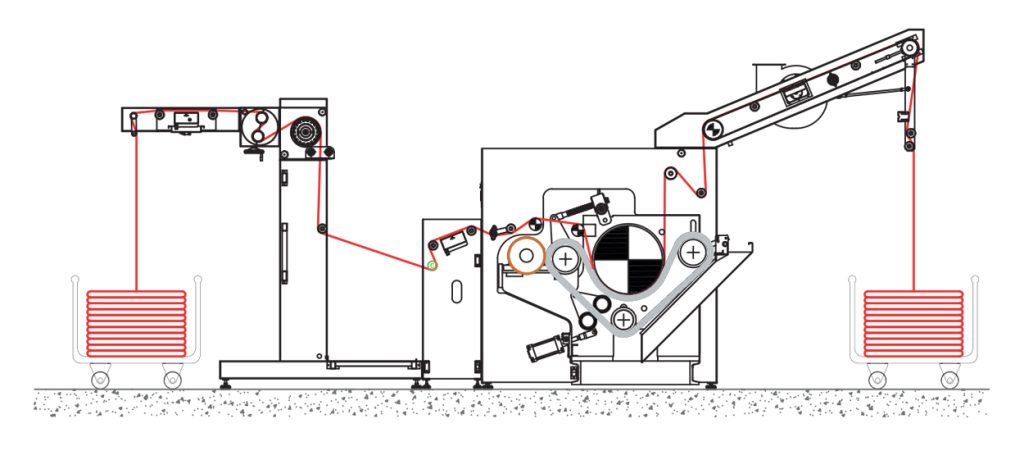

Fabric Inlet Section

Fabric centering unit and Load Cell roll controls the fabric rope movement through the inlet of the rubber blanket in a sensitive way which is especially suitable for light knitted fabrics.

▪ Opening Cylinder Group

At the entrance contains two motors. It especially plays an important role in opening right and left edges of knitted fabrics.

Master Heating drum in diameter of 610 mm with 11 kW motor gearbox drive, tested for 8 bars, and assembling special bearings which are resistant to high tempratures.

▪ Steamer box that moistens the fabric homogeneously at the entrance.

▪ Brushes that clean the particles accumulated on the main heating cylinder.

▪ Cooling the rubber blanket with water at various points.

▪ Roller grinding the surface of the blanket and the dust absorption system generated during this grinding process.

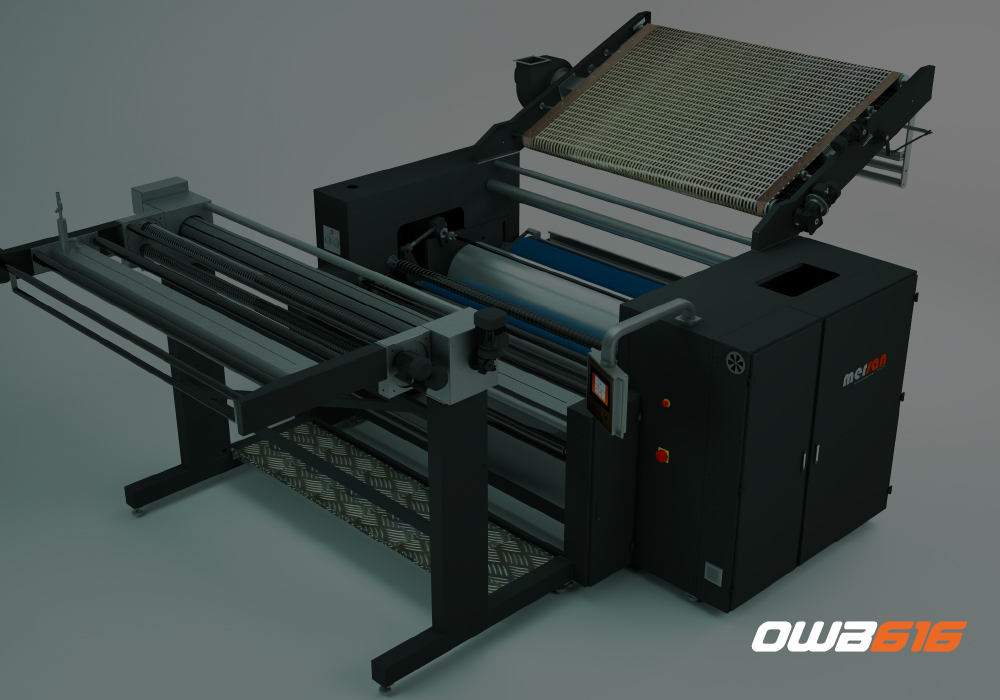

| HEATED DRUMS DIAMETER / WIDTH | Ø 616 mm. / 2600 mm. |

| WORKING WIDTH | 700 mm. – 2400 mm. |

| RUBBER SIZE | 2400x3962x67 mm. |

| WORKING SPEED (Max.) | 35 m/min. |

| VOLTAGE | 380-440V, 50-60 Hz |

| ELECTRICITY CONSUMPTION | 25 kW +/-5% |

| AIR PRESSURE | 0-6 bar |

| AIR CONSUMPTION | 50 NL/h |

| STEAM CONSUMPTION (Max.) | 60 kg/h |

| WATER CONSUMPTION | 1 m³/h |