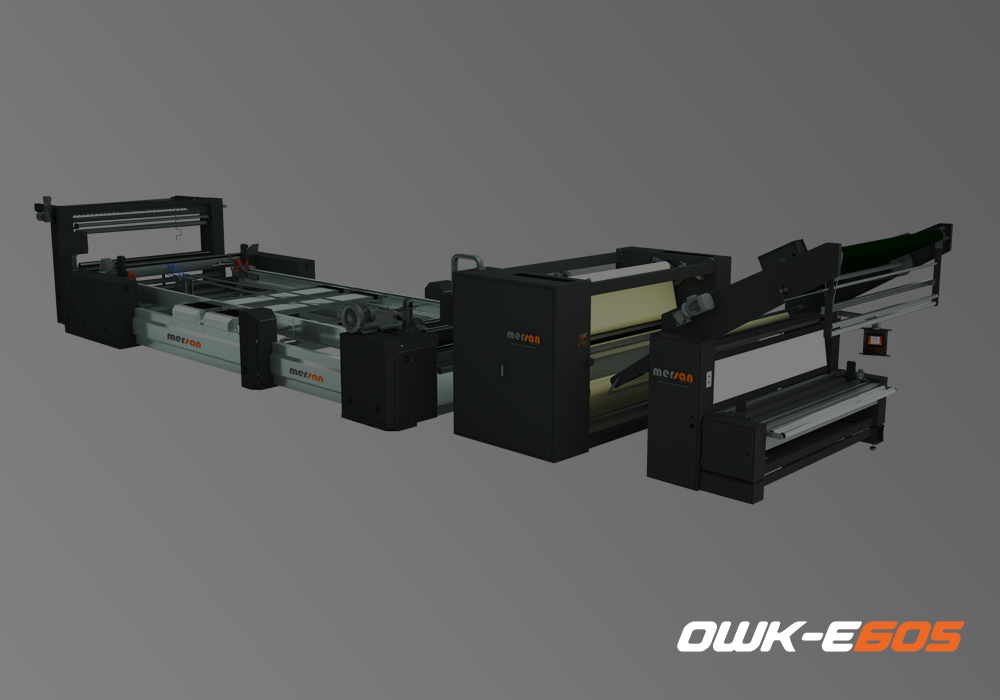

On knitted fabrics, the desired full surface compactness and shine can be obtained from the compression and pressing of the fabric between the felt, teflon and cylinder.

Fabric centering device and expander rollers Provides continuous monitoring and centering the fabric.

▪ Minimized fabric tension control.

▪ User friendly oparator platform.

▪ Independent driven expander rollers.

▪ Successful Pinning performance.

▪ Automatic chain tension adjustment

▪ Rail heating, auto lubrication&stainless steel chains

▪ Wider closing angle between conic&Parallel sections

Steam Box group Moisturizes

the fabric homogenously before compacting.

▪ Compacting Unit

OWK cylinders’ diameter 605mm with chrome coated and polished. The contact surface between the cylinder and compacting endless felt is 270 degrees. The total contacting surface area is 2828 mm for both cylinders. For this reason, the formation shrinkage of the fabric adds extra value and production.

▪ Fabric conveyor band and Cooling Unit

The fabric is cooled on the conveyor belt before the exit.

▪ Roller Exit fabric unit

Speed synchronization and, Fabric tension is controlled , Sensitive fabric edge sensor, detection of fabric edge in order to have precision edge roller.

| HEATED DRUMS DIAMETER / WIDTH | Ø 605 mm. / 2550 mm. |

| WORKING WIDTH | 700 – 2400 mm. |

| FELT SIZE | 2520x3950x20 mm. %50 Nomex %50 Polyester |

| WORKING SPEED (Max.) | 50 m/min |

| VOLTAGE | 380-440V, 50-60 Hz |

| ELECTRICITY CONSUMPTION | 38 kW / Dampening 42 kW +/-5% |

| AIR PRESSURE | 0-6 Bar |

| AIR CONSUMPTION | 50 NL/h |

| STEAM CONSUMPTION (Max.) | Max. 220 kg/h |