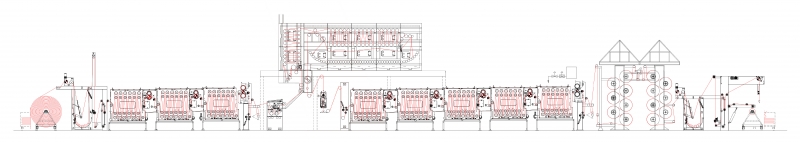

Increases your competitive Capacity with maximum System Efficiency and Product Quality,thanks to its functional and ergonomic Design. Woven Fabric Inlet and Outlet Equipment at Machinery, Wash-Off after discontinuously Desizing-Demineralization in Pre-Washing Section,or Wash-Off in the same after Continue Desizing and Demineralization-Steamer, Continue Bleaching with Impregnation and Steaming units’ features,Final-Washing, Neutralization and Cold Rinsing.The Washbox Types and Numbers are configured in accordance with the Type and Texture of the Product, the Process to be implemented,as well as the Production-Capacity needed.

Process: Enables Pre-Treatment Works like Desizing, Demineralization, Bleaching, Washing, Neutralization, Cold Rinsing with High Product Quality and Performance at once for the Grey Fabrics to be dyed,or printed,as Narrow or Open Width Textile Fabrics with Low Water,-Chemical,-Heat and Electricity Costs.

Working Widths: 1800 – 3400 mm

Wash-Off of Desizing Chemicals in Pre-Washboxes,after Discontinue-Desizing or Continue-Desizing by using of Desizing Steamer with Dwelling-Reaction Unit,and Wash-Off in Pre-Washboxes

Continue Demineralization Steamer with Dwelling-Reaction Units

Bleaching Impregnation Unit with Chemicals Dosage System

Bleaching Steamer with Dwelling-Reaction unit,

Combined Type with bounded and piled Fabric on Conveyor Rollerbed.

Washboxes-Conventional Bounded Up-and-Down Type

Neutralization by using of Acetic Acid and Cold Rinsing Bath

Washbox Fabric Capacities: 20 m single pass, 36 m double pass

Cylinder Drying Unit (optional): Steam heated, Cylinder Type, Energy Saving System

Waste Water Recovery System (optional)

Production Speed: 5 – 100 m/min